Polyethylene Foam Fabrication

Foamcraft USA fabricates polyethylene foam parts. Polyethylene foam is a semi-rigid, closed-cell expanded foam material in plain, anti-static, and cross-linked polyethylene foam, including polyurethane foam is too lightweight. If engineered properly, it offers multiple impact protection for any set of drop heights, weights, and G-force (rate of deceleration) combinations.

Cut Polyethylene foam parts offer a variety of advantages. This closed-cell material is tough and energy-absorbent as well as lightweight. Due to its moisture and chemical resistance, this foam will not mold or rot. It is also very easy to fabricate, so is a cost-effective option for your application.

Applications:

- Case Inserts

- Cushioning including padding, matting, and athletic impact resistance

- Industrial applications including Dewar caps & plugs and paint masks

- Flotation

- Insulation

- Spring Sub-Flooring

- Pouches

Polyethylene Sheets & Rolls

Foamcraft offers cut polyethylene foam parts in densities ranging from 1 to 9 pounds per cubic foot, and sold in:

- Contoured shapes

- Die-Cut Parts

- Sheets

- Rolls (including perforated rolls)

- Pouches

- Rounds

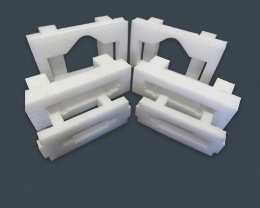

- Foam End Caps

- Cradles

Experts at polyethylene foam fabrication, our staff knows how to use these materials to their fullest potential to eliminate the breakage of your important products during handling or shipping.

-

Cross Linked Polyethylene

Cross-linked polyethylene foam, or XLPE foam, is a fine celled chemically cross lined material that is characterized by a micro-cellular structure. LEARN MORE

Cross Linked Polyethylene

-

Volara Foam

Volara is flexible closed-cell polyethylene foam that is cross-linked using an electron irradiation process, which results in a continuous, smooth surface LEARN MORE

Volara Foam