Foam Die Cutting Services

What is Die Cut Foam?

Die cutting is the technique of stamping foam parts using steel ruled tools or “dies” on a machine called a punch press. Any two-dimensional shape can be configured and cut on several types of punch presses to create a die cut foam. For example, the die cutting process can be used to create die cut foam end caps or protective foam packaging pieces.

Foam Die Cutting Advantages:

- Clicker presses are smaller and click very frequently.

- Hydraulic presses cut more slowly but over a greater surface area.

- Rotary die cutting machines use cylindrical dies to allow parts to get cut and propelled out at an extremely fast rate.

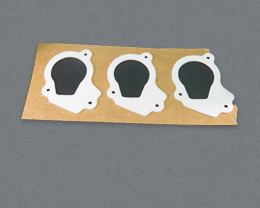

Foamcraft USA offers foam die cutting services for your unique application. Many of our punch presses allow us to kiss cut, a technology for when pressure-sensitive adhesives are used, and allows finished parts to be lifted off the release liner, automatically exposing the adhesive. Our largest press uses a traveling head technology that allows us to use full sheets of raw materials (both open and closed cell), thus eliminating preparatory steps saving time and money.

Die Cut Foam Parts

Our die cutting machine allows us to fabricate precise parts in a variety of shapes. Many of our die cut foam parts are used for the following applications:

- Packaging materials

- Case inserts

- Gaskets & seals

- Many more!

Materials Used:

We work with a variety of substrates, including:

We pride ourselves on our vast array of machinery and nowhere is that more evident than in our die cutting department. Find out why we are the die cutting experts and get a quote today on all our foam die cutting services!