Convoluted Foam Services

What Is Convoluted Cutting?

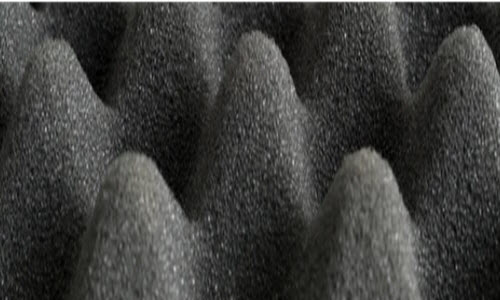

Convoluted foam, or egg crate foam, is common in bedding, packing, upholstery, sound insulation applications, and mattresses. Convoluted foam is environmentally friendly, easy to cut, and inexpensive compared to other foam solutions.

Convoluted Cutting Processes

Convoluted cutting is similar to skiving cutting which cuts one sheet into two half pieces, and can be made with ridged designs like peaks and valleys. The convoluted cutting process begins with a large flat foam sheet that is pressed by a long roller as a blade slices it. The pressure from the roller and the special cutting blade results in custom patterns with valleys and peaks.

Advantages & Benefits

The egg crate foam shape is a two-fold foam that is more responsive and distributed weight better than a standard thick layer of foam. The advantage to the texture is the breathable open-cell foam that adds a cooling advantage and dissipates heat. Convoluted foam is relatively cheaper to produce especially in large quantities.

When used in bedding such as mattresses and toppers, convoluted foam cone tips support and conform to an individual’s body shape allowing pressure point relief and preventative measures against bedsores. Convoluted foam services are common in the bedding industry due to their wide range of foam types and firmness. The foam can easily roll up for storage, is lightweight, and can be suited for all home décor applications.

Convoluted Foam Applications

Convoluted foam is very common in applications including:

- cameras

- instruments

- sound absorption

- other delicate equipment

The custom convoluted foam cutting absorbs shock, recovers its shape quickly, and is lightweight. The padding also acts as an anti-static preventative liner for packing electronics and reduces echo and reverberation for recording environments.

Custom Convoluted Box Packaging

Foamcraft USA works with you to create turnkey custom packaging solutions that provide superior cushioning against vibration and impact forces, which protect items during handling and transportation. Our experienced engineering team can specifically engineer boxes with the proper height and density utilizing convoluted foam tops and bottoms that can adequately protect items by pressing down and keeping objects from moving around.

The Foamcraft Difference

The design of our machines helps to improve the foam's durability, longevity, cost and is aesthetically pleasing for every project. Unlike the traditional convoluted cutting method, our machines enhance the foam's support performance, strength, and longevity.

For over 50 years, Foam Craft USA has specialized in custom convoluted cutting for customers across the Mideast area of the United States. As the number foam provider nationwide, we house a wide range of foam materials and stay up-to-date with the latest state-of-the-art convoluted foam fabrication techniques. We are dedicated to providing our customers with premium convoluted foam services, materials, and products.